What is Business Process Reengineering? That’s what a number of business owners ask me often, so I thought i would create this guide to help you understand what it is and how to use it to benefit your business, whether large or small.

So, what is business process reengineering?

It’s simply a tool that looks at systems or processes from end to end, designed to make step changes and drastic shifts in improvement.

This improvement normally sits within:

- Productivity

- Delivery

- Cost

- Quality

- Safety

You’ve heard of Incremental improvement, right?

Well, business process reengineering is the opposite.

It’s about making large, focused changes that transform the process from start to finish.

What’s a process?

Where there’s a sequence of activities, there’s a process.

So, where there’s a process, there’s an opportunity to ‘reengineer’ that sequence of activities to drastically improve the output.

The difference between making smaller continuous process improvements and answering the question of what is Business Process Reengineering……. well, it’s about the impact on the business.

Ideally, you want to focus your efforts on the systems that will get you the biggest results.

Focus on the vital few things that will get the maximum output.

And so, look at your key processes and find the current most critical one to improve first.

“The 80 / 20 Rule – 20% of processes, activities and inputs will create 80% of the impact.”

Typical systems that have a large impact on the wider business performance are higher level processes, like:

- How a product is manufactured and delivered to plan?

- The quality of data entry and processing in a call centre

- How a service is delivered on time and in budget?

- How a business captures its leads, and turns quotes around quickly?

- How the business invoices and processes payment?

- How quickly and accurately new products can be released to the market?

These are just some examples of what I mean. I’m sure you have plenty more.

So, when you’re looking at end to end processes, at a more top level view, then business process re-engineering can help.

It means you must give the project strategic focus.

You must also give it the right amount of time.

And so too, resource – teams must be given clear roles and targets to improve the process.

And where permitting, a decent budget to invest in improvements, like IT, infrastructure and other things that can help transform the process.

Business process reengineering or BPR for short, is often referred to as business improvement or business process improvement (BPI).

Each reference the same outcome: it’s about looking at your processes strategically, and making drastic improvements to improve customer satisfaction and the business’ bottom-line performance.

What is Business Process Reengineering and How Does it Link to Process Improvement?

What is Business Process Reengineering In the Context of Non-value Added Activities? Well, In one of my previous articles, I explained what NVA and VA is in more detail.

NVA, is the sticking point or bottleneck in any process or system. It stands for non-value-added activity, which ultimately means activities, which do not add value in the eyes of the customer.

What do I mean? Well, if you can understand exactly what the customer wants from your business, then you can understand what activities are value added and which aren’t.

So, BPR is a process in itself, which allows the team to come together and analyse a specific process or system, and then get to work to drive out as much NVA activity as they can.

Because if you can reduce NVA, you can have a drastic impact on:

- waiting times between processes

- getting things right first time

- improving communication

- reducing lead times

- reducing stock requirements

- improving productivity

- increasing the response time to customer enquiries

- simplifying processes

- reducing costs

- increasing profitability

Every Process Has Outputs

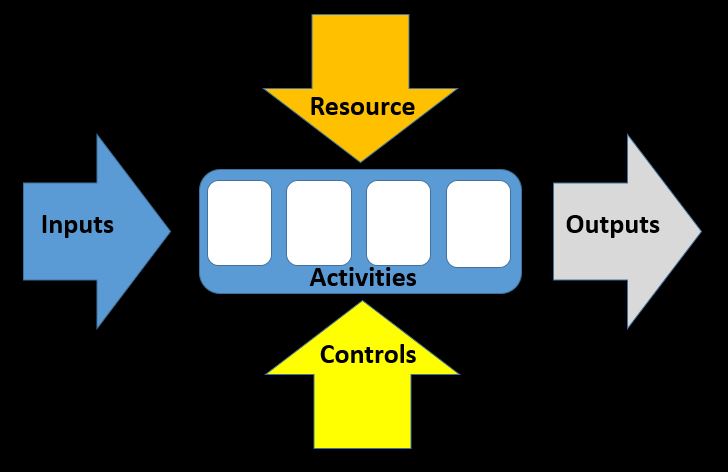

All processes follow the same framework.

They have an input.

An output.

And in the middle, they have a sequence of activities, which need resource and controls to complete.

Here’s what I mean:

The performance of the process is governed by the quality of its inputs, resource, controls, and activities.

So, if you have poor processes that captures inputs inefficiently, then perhaps the end result may be a costly, slow overall process, with poor quality and long lead times.

If the ‘in-process controls’ are weak or not performing particularly well, perhaps the quality of the output will be effected, the cost to administer the process may be high through rework, warranties and defects, and the lead time will be long, with delays in delivery to the customer.

If there’s insufficient resource or skills, then the same result could happen. Unhappy customers could be queuing at the door. Complexity and chaos in your processes, poor delivery and staff morale, too.

So, what is business process reengineering? It’s about optimising the inputs, controls, resources and the in-process activities. It’s also about redesigning them in a way that they link symbiotically, and which maximise value to the customer….. because adding more value means being more competitive…….and improving performance to the business’ bottom line.

The Critical Steps to Business Process Reengineering

Here’s the basic steps to mapping and remodelling your key business process:

- We need to map our current process first. This is often called the ‘as-is’ process or the current state.

It’s simply a matter of walking your process, with your team and taking notes of every step along the way.

- Identify the value added and non-value-added steps – hunt out the NVA so you can see where the major bottlenecks are and also where you can start to see where things can improve

- Understand the costs incurred in the current process, so you can then agree what the costs should be in the improved process, and then set yourself improvement targets

- Understand the impact of the NVA steps and bottlenecks on the overall performance of the process

- Then map the ‘Future State’ process, or sometimes called the ‘To-Be’ process

- Test the future state on a smaller scale and then upscale quickly when it works and then lock in the new way, making amendments using continuous improvement

A Data Driven Approach

What is business process reengineering? It’s a data driven approach.

When making improvements, you have to know what you’re up against, before you can improve it.

That means measuring it……

How is the process currently performing?

How much is the current process costing the business?

- This could be in terms of cost of errors

- cost of labour, including overtime

- waiting and delays

- lead time, which will affect the length of time it takes to get paid

- cost of warranties and returns

- Cost of poor information and repeated activities

- Cost of poor quality delivery of the product or service (you may be too expensive for your market, due to the fact that your processes are too cumbersome)

These are just to name a few.

And when designing your sparkly new process, you want to focus on two key ways to help drastically improve performance:

Drastic impact #1: Delayer Decision Making. Use a cross functional team to work together to manage the process. This means people from different departments coming together to manage the day-to-day performance of the entire process.

By doing this, you are de-layering the communication and decision making, making the process run faster and more agile.

Drastic Impact #2: Automate Routine Tasks. Automate as much of the administration and communication flow as possible. That means being prepared to invest in the most appropriate information technology for your business.

It’s worth looking at cost / benefit analysis and pay back. I.E. “If we purchase this software, how long will it take to make a return on this investment? Is the initial cost going to benefit the process, customer and business in the long run?”

Is This Concept Just for Large Organisations?

Absolutely not!

Where there’s a process there can be improvements made to any business in any industry or sector.

No matter how big or small the business or process is.

The key point to note is to include a small team right at the start.

Buy-in from employees comes with opening up to them. And quite, frankly, success doesn’t come from one person. It comes from teams and many individuals working together in a system.

So, whether a large or small organisation, you should try to stick to the following steps:

- Pick the process with the biggest problems, or strategic importance. Try not to focus on small departmental activities. Try to create a massive step change, and that would mean stepping back a little and looking at the larger process, which crosses departments and functions.

If you are looking too low at your process, look up a level or two, and try to focus around level 3 (depending on your organisation’s size).

Here’s what I mean: there are different levels that you can view any process.

The top Level –at the organisational level, which may just show a simple top level view, like this. We’ll call this level 1

Top level process mapping view

The Next Level Down – may show the main processes of the business. These are typically around 5 or 6 key processes that run across your business. We’ll call this level 2

Level 2 Process Mapping view

The next level down – this can be seen by picking one of the main processes and drilling down to view its individual steps. You are now viewing the end-to-end process. We’ll call this level 3

Level 3 process mapping view

At the next level down still – you can pick a part of the process and drill down further to see individual steps or activities, which normally can be seen conducted by a small team or department. At this level, you are now looking at a small portion of the big process but in a highly detailed view. We’ll call this level 4

Whilst you may want to drill down to level 4 as part of the detailed analysis and process improvements during the business process reengineering project, the level to map is at level 3, where you can see and map the whole process from end to end, across departments and teams.

These levels are just for example purposes and may vary depending on your business size, but I’m sure you get the picture!

The point is, you need to look at the end to end process view, that spans across departments.

So how do you map the process? It’s easy, with a pack of post its, and a pen!

- Walk the process with a small elected, cross functional group

- Get everyone to map it individually, on paper, and based on their interpretation

- Return, discuss and agree the process as a team, using good old post-its and a flip chart pad.

- Once you have this on paper, make a few amendments and compile the final draft.

Then go Hunting for Tim Woods

And once you’ve found Tim Woods, for every activity identified, look to do one of three things, to improve productivity.

Option One: eliminate the activity there and then. If you don’t need to do it, then get rid of it! Sometimes processes informally evolve and activities creep in that made sense once, but don’t now. If it’s not needed anymore, then just get rid.

Option Two: if you can’t single-handedly eliminate that activity because it needs to be done to support that process, then look to reduce the time it takes to do this activity. Some things like processing data or confirming information have to be done, but how can you do it in a slick and clean way (cue automation……)

Option Three: if you can’t physically reduce the time it takes to do that activity, then look to combine it with other non-value-added activities, so you can process two activities at the same time.

Perhaps someone gets the material whilst another sets a machine up, is a good example of this in the manufacturing world.

Either way, by following the three-option rule with every NVA activity, your productivity will improve, and so too your process.

Factor in other costs – cost of labour and overtime, and processing, and you should have a great end-to-end understanding of your process.

Now Re-Engineer Your Process from The Ground Up

The next step is to get bold. Redesign your current process with zest. Pick out drastic ideas.

Use automation – where can you use technology to improve flow and productivity? What impact will it have? Is it worth it, or is there another way?

Create clear team ownership, so everyone knows what’s expected to manage the new day to day process. How can you de-layer the decision making and communication? How can you improve flow?

- Flow of ideas

- Flow of communication and decisions

- Flow of reviews and actions

- Flow of leadership, perhaps

The next is to create the major milestones and project plan;

- what actions need to be taken to make this future state process, a reality?

- How long will it take? Clearly state owners and timescales.

And Implement Trials to See If It Provisionally Works

At this point, it’s about trialling on a small scale and then ramping up if results are to plan (or check, adjust and go again, if they aren’t.)

Its then about managing the project through to completion, with regular status updates to keep on track.

And when the processes are in place, locking the new changes in is the next challenge, by providing standard processes, training and reviews to ensure that everyone is adopting the new ways of working.

We are now in change management territory, so leading teams to adopting the new ways of working, is critical.

- Give them time to learn new ways and thinking

- To learn new skills

- To adjust and transition through their change curve

- And celebrate and reward the new behaviours and outcomes

Most of all, ensure the new process is being adhered to.

So too, the teams are monitoring performance regularly, so they can continuously improve the process, furthermore.

The Key points

So, what is Business Process Reengineering?

It’s a systematic process in itself, designed to make a drastic improvement to your key processes.

Whether you’re in a large or small business, business process reengineering can make large-scale improvements to your business capability. It can provide great value to customers and does it in a way that improves your bottom line performance.

The key points to remember are:

- Pick the right level of mapping. Don’t go too high, where you can’t get enough detail, and don’t go too low, where you focus on one sub area of the process. Focus on the level which cuts across departments

- Look to automate administration and communication using technology

- Delayer the decision making and information flow, by focusing on a cross functional team to oversee the process and make day-to-day decisions

- Look for NVA and drive it out through the 3 option rule

- Focus on managing change to ensure people adopt the new activities

- Continuously improve day by day and review performance regularly

Return from What is Business Process Reengineering, to Business Improvement Home Page